Manduka is one of the most respected names in the global yoga world, known for its ultra-durable PRO mats, grippy eKO natural rubber mats, and eco-conscious accessories. Many yogis assume the mats are handmade in boutique workshops or crafted in the U.S. because of their premium reputation and long lifetime guarantee. But where Manduka mats are actually manufactured—and who makes them—is a fascinating story of global sourcing, sustainability, and carefully selected production partners.

Understanding Manduka’s manufacturing network reveals why these mats have become a gold standard for yoga studios and practitioners everywhere.

Manduka PRO Mats: Made in Germany

The legendary Manduka PRO and PROlite mats—the brand’s most premium and durable range—are manufactured in Germany. This has been true since their launch and remains one of the biggest differentiators between Manduka and other yoga brands.

German production is central to the PRO series because the mats use closed-cell PVC foam that requires precision engineering, strict environmental controls, and high-grade manufacturing technology. Manduka works with a long-established German manufacturer that specialises in high-density, heat-compressed PVC mats used in both fitness and industrial applications.

These mats follow a certified emissions-free manufacturing process, which is why Manduka frequently markets the PRO line as OEKO-TEX certified and built to last a lifetime. German production ensures the mats maintain their famously consistent density, cushioning, and durability—qualities that lower-cost factories often cannot replicate.

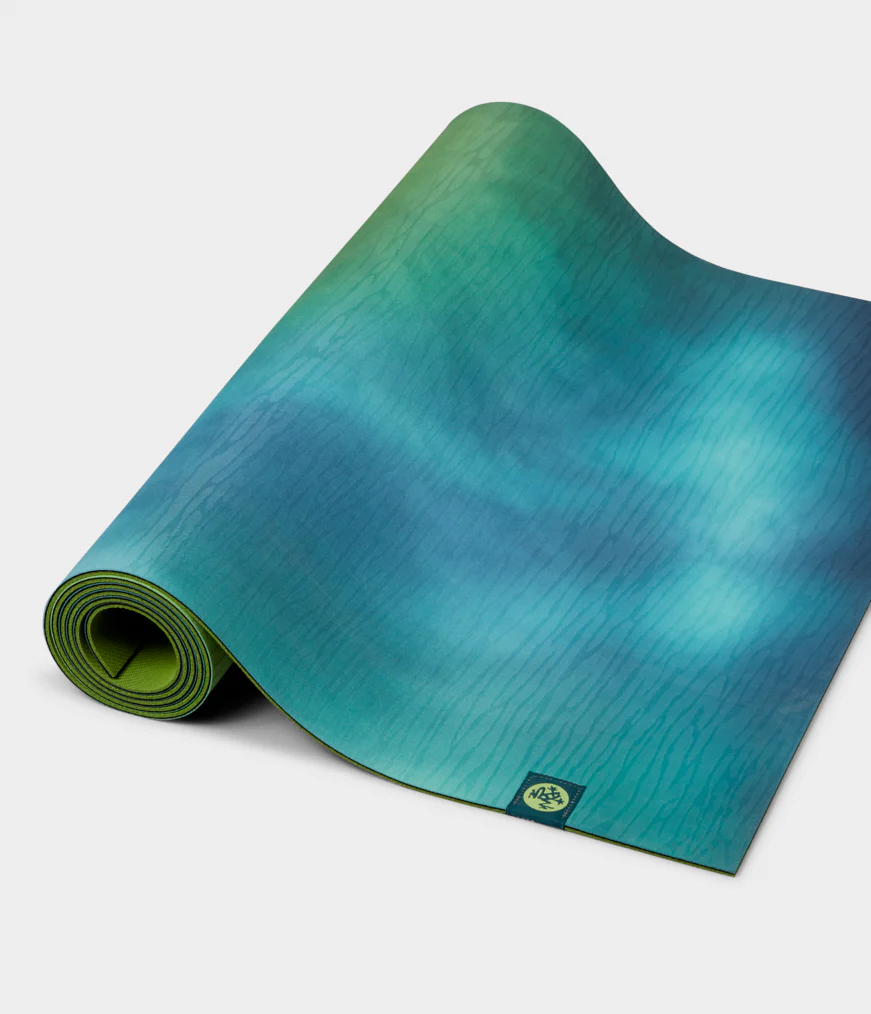

Manduka eKO Mats: Made in Taiwan (from Natural Rubber)

Manduka’s popular eKO series, which includes travel-friendly rubber mats and thicker natural rubber options, is manufactured in Taiwan. These mats use sustainably harvested natural rubber sourced mainly from Southeast Asia.

Taiwan is a global leader in natural-rubber mat production because it has the technical expertise to:

- process natural rubber without toxic softening agents

- create high-grip surfaces using eco-processing

- maintain consistent mat thickness and controlled density

While Manduka does not typically publish factory names, the eKO mats come from specialised facilities that follow strict clean-processing standards, ensuring no harmful foaming agents or non-biodegradable plasticizers are used.

Manduka GRP and Hybrid Mats: Manufactured in China

Manduka’s GRP (Grip) Series and some hybrid or specialty mats are manufactured in China, primarily at factories specialising in polyurethane (PU), rubber blends, and the microfiber-topped surfaces used in hot yoga mats.

China’s advanced PU-molding plants allow Manduka to produce mats with:

- extreme absorbency

- textured moisture-wicking top layers

- “liquid rubber” feel for hot yoga

- high-friction grip even in sweat

Although China-made products sometimes raise concerns among eco-focused consumers, Manduka enforces strict environmental and quality-control standards. Many GRP mats are made in factories certified for responsible production, ISO quality systems, and materials sourcing compliance.

Manduka Travel Mats and Accessories: Mixed Manufacturing Locations

Manduka’s lighter mats, foam blocks, yoga straps, bolsters, and apparel come from a mix of China, Taiwan, and Vietnam, depending on the material. For example:

- Cork blocks are usually sourced from Portugal

- Foam blocks come from Chinese or Taiwanese specialist foam plants

- Straps and prop textiles are often manufactured in Vietnam

The brand prioritises factories with eco-certifications, fair-labour standards, and speciality expertise rather than basing production in a single country.

Why Manduka Uses a Multi-Country Manufacturing Model

Manduka strategically selects manufacturing locations based on material type, technology needed, and environmental standards rather than cost alone. The company uses a distributed supply chain because no single region specialises in all materials needed:

- Germany is unrivalled for precision PVC engineering

- Taiwan leads in natural rubber yoga mat production

- China excels in PU-topped hot yoga mats and accessory assembly

This approach allows Manduka to offer a broad range of mats, each optimised for specific performance characteristics—grip, durability, portability, eco-friendliness, or cushioning—without compromising on quality.

Quality Control and Environmental Commitment

One of the core reasons Manduka mats cost more than generic brands is the level of quality assurance the company demands from its manufacturing partners. Manduka maintains oversight through:

- OEKO-TEX standards for the PRO line

- sustainable rubber sourcing for eKO mats

- zero-waste PVC manufacturing processes

- rigorous durability testing

- ethical manufacturing certifications for partner factories

This consistent quality control across borders is why Manduka mats are known to outlast most competitors—some PRO mats remain usable for over a decade of daily practice.

Conclusion: Designed for Yogis, Made by Global Specialists

So, who makes Manduka yoga mats?

Manduka’s mats are designed in the U.S. but manufactured across a global network of highly specialised partners:

- Germany → PRO and PROlite series

- Taiwan → eKO natural rubber mats

- China → GRP hot yoga mats and selected accessories

- Portugal, Vietnam, China → blocks, straps, bolsters, textiles

Instead of owning factories, Manduka collaborates with industry-leading producers capable of meeting the brand’s high environmental and performance standards.

For yogis seeking transparency, this manufacturing story highlights why Manduka mats consistently stand out in durability, sustainability, and long-term practice value.

Leave a Reply